In the realm of industrial processes, certain gases play a vital role. One such gas, Sulfur Hexafluoride (SF6), has garnered significant attention due to its unique properties and wide-ranging uses. Its exceptional electrical insulation capabilities, chemical stability, and high dielectric strength make it particularly suitable for the following uses:

Electric power industry

One of the primary uses of SF6 gas lies in high-voltage equipment like circuit breakers, gas-insulated switchgear (GIS), and transformers. It serves as an effective electrical insulator, facilitating the safe and efficient transmission of electricity over long distances. In these systems, SF6 gas enables compact and reliable installations, reducing the need for large-scale electrical infrastructure.

Metal processing and casting

SF6 gas is commonly used as a protective gas to prevent oxidation and impurities during the manufacturing of magnesium and aluminium-based components. By acting as a shield against Oxygen, SF6 facilitates high-quality production, reducing defects and improving the mechanical properties of these metals.

Medical industry

SF6 gas also finds limited use in medical applications. Its unique properties, such as high dielectric strength and thermal stability, make it suitable for various medical equipment, including laser surgery devices and eye surgery instruments. It is also used as a contrast agent for medical imaging, such as magnetic resonance imaging (MRI), due to its ability to enhance image quality.

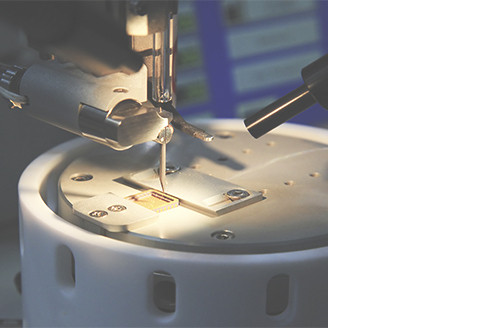

Semiconductor manufacturing

SF6 gas is widely used in semiconductor manufacturing processes as a highly efficient etching and cleaning agent.

Accelerators in particle physics

SF6 is used in accelerators in particle physics as an insulating gas to prevent electrical breakdown and maintain stable electric fields. It is also used as a quenching medium to suppress electrical arcs that may occur, ensuring the safety and efficient operation of the accelerator components.

Tracer gas

SF6 is extensively used as a tracer gas for gas leak detection in underground pipelines and in air conditioning systems. It also finds applications in environmental monitoring, namely in greenhouse gas monitoring and air quality monitoring.

Danger of SF6

While SF6 plays a crucial role in various applications, it is important to recognize the potential dangers associated with SF6 leakages:

- One of the most significant risks associated with SF6 gas is its impact on the environment. SF6 is a potent greenhouse gas. According to the European Union's F-Gas Regulation (517/2014), its global warming potential (GWP) is 22 800, thousands of times that of Carbon Dioxide (CO2) over a 100-year timescale. This means that even small leakages or emissions of SF6 gas can have a significant impact on the environment and contribute to global warming.

- Another potential danger of SF6 is its high density and ability to displace Oxygen (O2) in case of leakage. Lack of O2 is dangerous for people, as it causes asphyxiation.

- Finally, SF6 gas can be dangerous if it is exposed to high-energy arcs or sparks. When SF6 is subjected to an electric arc, it can decompose into byproducts - Sulfur Dioxide and Hydrogen Fluoride. Such gases are corrosive to different equipment and very harmful to human health. The 8-hour time weighted average (TWA) exposure limit is established at 1000 ppm.

To mitigate the risks associated with SF6 leakages, proper handling procedures, maintenance programs and established safety protocols must be followed by operators.

Implementing effective gas detection systems and conducting regular inspections are essential steps in maintaining a safe working environment.

Please see the Featured Products section below to learn more about instruments for early gas leak detection and warning offered by Evikon MCI.